Бесплатный фрагмент - DUBINA 2021 ENG

Revolutionary technology

The most powerful in the universe

“The use of electric transport

the best change in the 21st century”

Anton Dubina

We live in a world of evolving technology. A car is a technical device made up of many parts that change with technology. There are over a billion internal combustion engine vehicles registered in the world today. Toxic substances in exhaust gases cause lung disease and cancer in people living in cities. The design of an electric car does not have large mechanical components such as a starter, carburetor, gearbox. A car with an electric motor accelerates faster. It is in many ways superior to a car with an internal combustion engine. All the wonderful possibilities of the electric drive have not yet been revealed. It will take many years before its properties are fully realized.

In 2014, I started working on an electric car project. At the time, I was surprised at the lack of electricity-powered cars in cities. People can come home from work and charge the car at night, when the electricity tariff is lower, and go about their business in the morning without wasting time at the gas station. But somehow they don’t. Probably because there are few models of electric cars in the world and their prices are too high. So I made the decision to make a nice and inexpensive electric car.

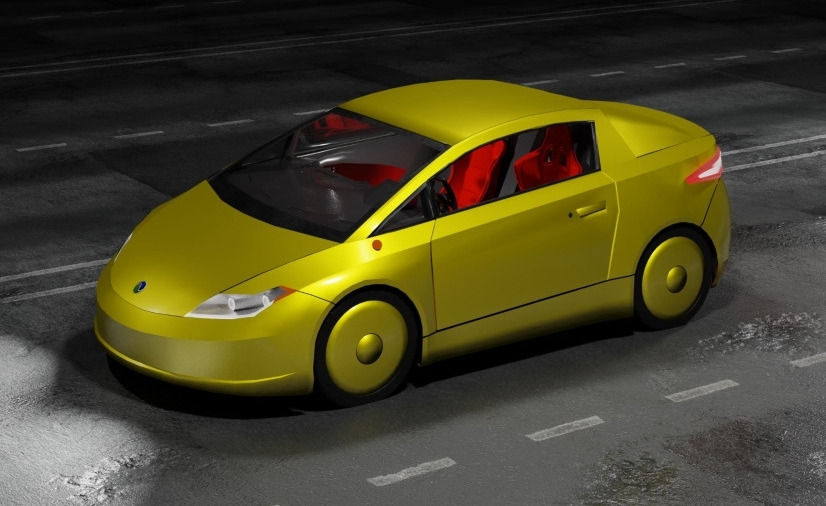

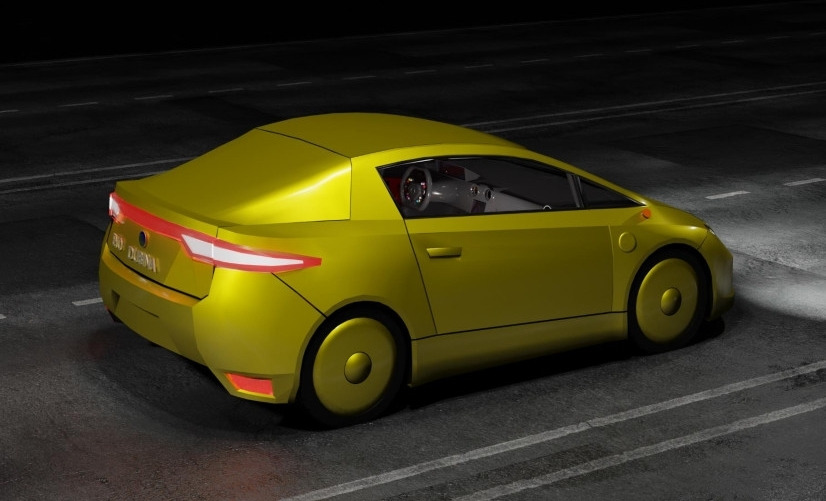

When designing the DUBINA EVO, I was guided by rules that improve the design. The desire to create the perfect car helped me make the right choice and find the right solution. The distinguishing feature of my sports car is that it combines the best properties with optimized value for money. Car production is carried out with minimal material costs with a fast, streamlined mechanism. The entire production process is carried out in a small factory. To avoid stopping the production process, assembly operations independent of each other. When making a car, we must not forget about ecology. A large number of parts are made from recycled household and industrial waste. Our responsibility is to keep our planet green, the sky blue and the horizon bright. This issue presents my results for 2020. During this year, many technical solutions have been made that have improved the design of the car.

I am interested in your feedback. As a reader of this book, you are the most important critic. Your opinion is valuable to me, and I would like to know what went right, what could be done better, what topics would you like to see and any other wishes you might have. You can send your messages by email.

e-mail: dubina.corporation@gmail.com

website: www.dubina.biz

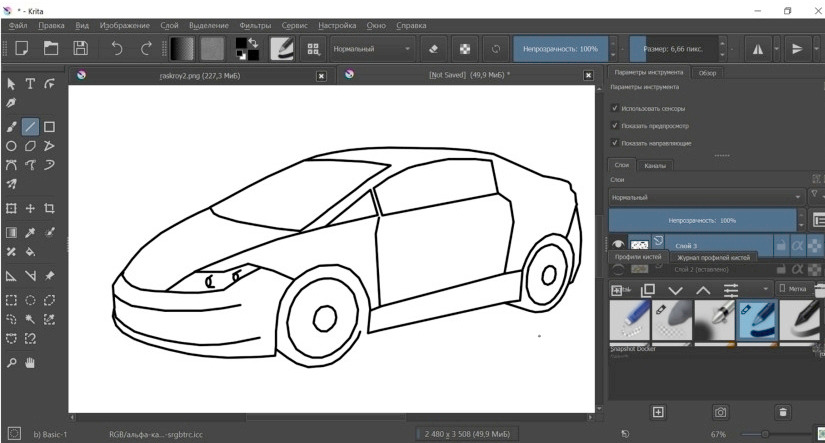

Materialization visualization

The basis of the project activity is software. Design tools are programs that perform various functions. The creation of the DUBINA EVO vehicle information model began with a preliminary design. The sketch was created in the free bitmap graphics editor Krita. It is open source software included with KDE. Krita is developed primarily for artists and photographers and is distributed under the terms of the GNU GPL. The program supports non-destructive editing of layers and masks, work in various color spaces and with various color models — RGB, CMYK, LAB, in the mode from 8 to 32 bits with floating point per channel. In addition, popular filters (such as unsharp masking), adjustment layers, masks and dynamic filters, as well as a series of retouching tools are implemented. However, the main priority of the developers is the realization of opportunities for artists. The concept of the car, its overall dimensions and design features were presented in the draft design. After determining the main dimensions and design features, drawings of the future car were created.

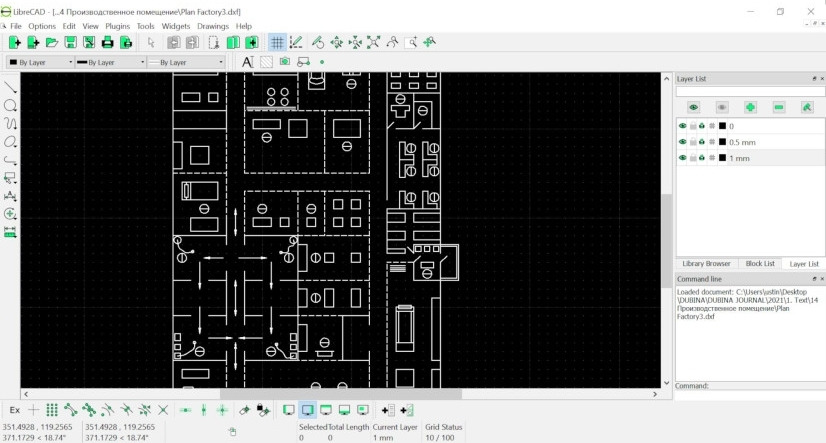

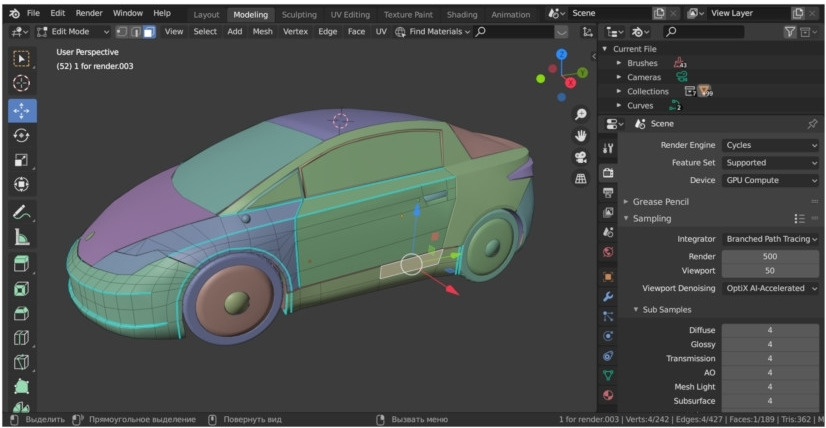

Drawings were made in the LibreCAD program. LibreCAD (formerly CADuntu) is a cross-platform, open and free CAD system for 2D drafting and design, built on the basis of QCad. LibreCAD allows you to solve problems of two-dimensional design, such as the preparation of engineering and construction drawings, diagrams and plans. Works under Linux, Windows and Mac OS X operating systems. Distributed under the GNU General Public License version 2. The source code is written in the C ++ programming language using the Qt libraries. Further, a three-dimensional model was built using the drawings. The Blender program is optimal for 3D modeling. Blender is a comprehensive program that combines all the current 3D modeling capabilities. The program is not demanding on the characteristics of the computer, it is possible to carry out design planning, organize an assembly structure and prepare a model for printing on a 3D printer. The use of all basic types of modeling: free forms and sculpting, working with solids (including direct editing), the ability defining parametric dimensions, as well as support for obj and stl formats as imported geometry. All elements that are modeled can be used as further templates for work. The software supports various 3D file formats for import and export, including Alembic, 3D Studio (3DS), Filmbox (FBX), Autodesk (DXF), SVG, STL (for 3D printing), UDIM, USD, VRML, WebM

Three-dimensional models of car parts were assembled into assembly units and connected to the main parts of the car. The car body was built in sculpting mode. The construction was started by creating one polygon, which was split into 4 equal polygons. Adding one polygon after another gave the body shape. In places requiring more polygons, polygons have been subdivided by the required number. After constructing and editing the longitudinal half of the body, the symmetry modifier was applied. The modifier creates a symmetrical copy of the part. The resulting part changes its shape when the original part changes its shape. By connecting two symmetrical parts of the body, the result is a body when changing, the shape of which on one side changes the shape of the other side. To give the body smooth, smooth lines used three-dimensional patterns. A cylinder was used to build an even circumference of the wheel arches. By applying the cylinder to the wheel arch as a template, the polygon lines were aligned. To draw straight lines on the doors and the threshold of the case, rectangular planes were used. Three-dimensional patterns allow you to check the straightness of polygon lines from all sides. To visually determine the smoothness of the shape of the case, materials with a glossy surface are used. The visual determination of surface smoothness is influenced not only by the type of material, but also by the color.

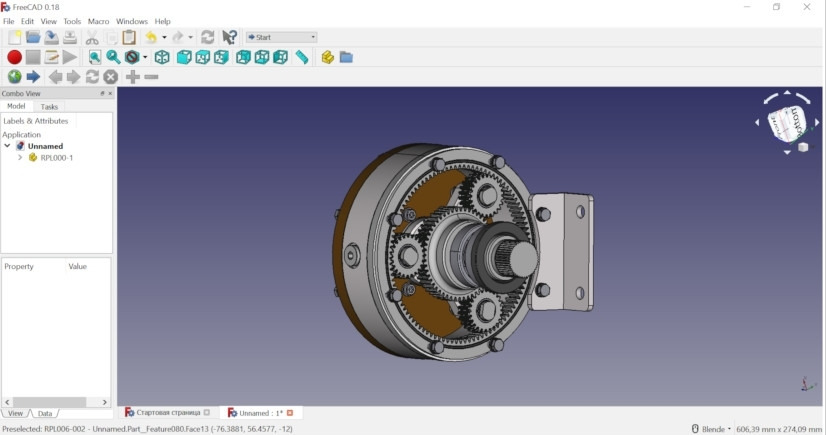

Details of mechanisms, gears of reducers were made in FreeCAD program. FreeCAD is an open source general purpose parametric CAD system (based on the LGPLv2 + license). The basis of geometric modeling of solids in FreeCAD is the principle of boundary representation, at the same time there is support for polygonal meshes. The geometric core of FreeCAD is OpenCASCADE. In addition to mechanical engineering tasks, FreeCAD can be used for tasks such as architectural design, or engineering analysis by the finite element method. Freecad supports over 30 file formats for importing. For the manufacture of car parts, 3D printing was used. 3D printing technology is universal. Part size for 3D printing is limited only by the size of the printer. A 3D printer is a peripheral device that uses the method of layer-by-layer creation of a three-dimensional object from a digital 3D model. No additional equipment is required for 3D printing. All types of parts are produced on one printer. In order to print a part on a 3D printer, you must first convert the original 3D model format into a G-code. G-code is a conditional naming of the programming language for numerically controlled devices (CNC). It was created by the Electronic Industries Alliance in the early 1960s. The Slic3r program is used to convert STL format to G-code format.

In this program, you can set the print speed, fill factor and more. After conversion, the file with the G-code is loaded into the 3D printer. Due to layer-by-layer shaping, parts of any complexity can be produced. Various materials are used for 3D printing. The most common PLA, ABS, PVA plastics, nylon, rubber, metal powder. The most productive 3D printing process is the stereolithography process. In the process of stereolithography, a layer of material is formed over the entire surface area simultaneously. The bright rays of light from the projector strike the clear glass. The glass is at the bottom of the bath with liquid light-curing material. A projector under the glass transmits a cross-sectional image of each part of the part. Thus, the material on the glass hardens and is pulled layer by layer up from the bathroom.

The car is controlled by a program written in the Arduino IDE. It is a cross-platform application (for Windows, MacOS, Linux) developed in C and C ++. It is used to write and download programs to Arduino-compatible boards, as well as to boards from other manufacturers. Source code for The IDE is released under the GNU General Public License Version 2. The Arduino IDE supports both C and C ++ using special structuring rules. The Arduino IDE provides a software library from the Wiring project that provides many common input and output routines. User-written code only needs two basic functions to run the sketch and the main program loop, which are compiled and linked to the program stub main () to an executable loopback executor with the GNU toolchain, also included in the IDE distribution.

Towards mass production

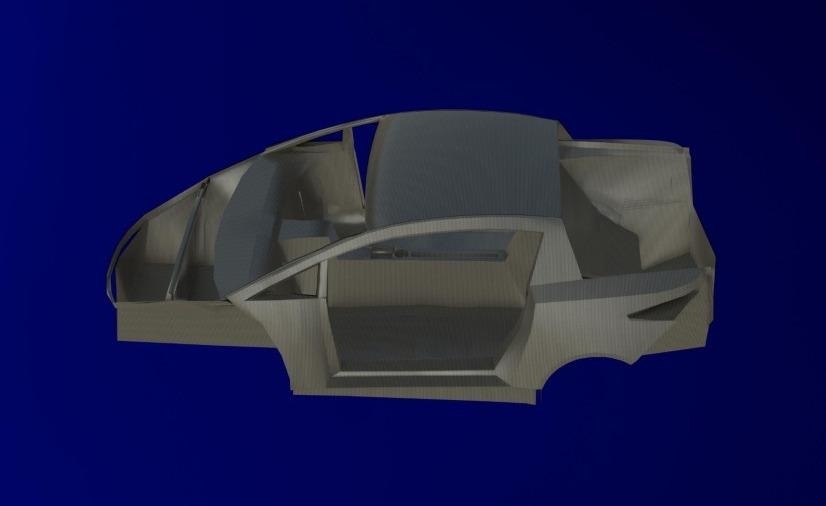

The car body is the most important constructive, most responsible, material-intensive and expensive part of the car. It makes up about half of the car in terms of weight, cost and manufacturing complexity. The body is the basis for the installation and fastening of all systems and mechanisms of the vehicle. The body ensures the safety of the vehicle. The body structure and its parameters have a serious impact on the performance properties that ensure the movement of the vehicle (maneuverability, stability, smoothness,), and on performance properties not related to vehicle movement (capacity, strength, durability, maintainability, suitability for loading and unloading). DUBINA EVO has a fiberglass monocoque body. He perceives all the loads that act on the car while driving. This means that all elements of the body, with the exception of doors and hatches, are load-bearing. The body support system allows you to reduce the weight of the vehicle, its overall height, lower the center of gravity and, therefore, increase its stability.

The design of the monocoque body consists in the most rational distribution of material in each element, allowing the best use of the maximum possible load-bearing capacity of the material. In order to give the structure a clear and continuous shape, providing direct transfer of the load from the point of its application to the point at which the reaction occurs. The structure of the monocoque body must be rigid enough to allow precise control, be light enough to allow inertial loads and the loads caused by the oscillatory angular movement of the sprung parts about the vertical axis were small, to be strong and durable to withstand the cyclic road loads, the loads from the power plant, the driver and the passenger. Hence, it is clear that the structure of a car is assessed not by strength, but by rigidity, and the study of the state of the structure is associated with the study of its deformability rather than the stress state. Bending deflections in the middle of the vehicle span should not exceed 1.3 mm, and the deformations of the contour of door openings should not exceed 1.2 mm in the event of a load concentrated in the middle of the span equal to 6700 N. Fiberglass is not as rigid as steel or aluminum, therefore, reinforcing plates, brackets and stiffeners are used in the body structure. Fiberglass is a durable and lightweight material.

Another great advantage of fiberglass is the absence of corrosion. Important parts that contribute to the overall rigidity of the structure are roof rails, head rails and pillars of the windshield frame, door hinges, front and rear body frame spars, rear side panels, door pillars. The body supporting system made of fiberglass provides good insulation of the passenger compartment from vibration and noise of operating units and mechanisms, as well as from the noise of tires that occurs when they roll on the road surface. Body parts are made of fiberglass 2 … 3 mm thick. The body of the DUBINA EVO is shaped like an engine compartment, a passenger compartment and luggage compartments.

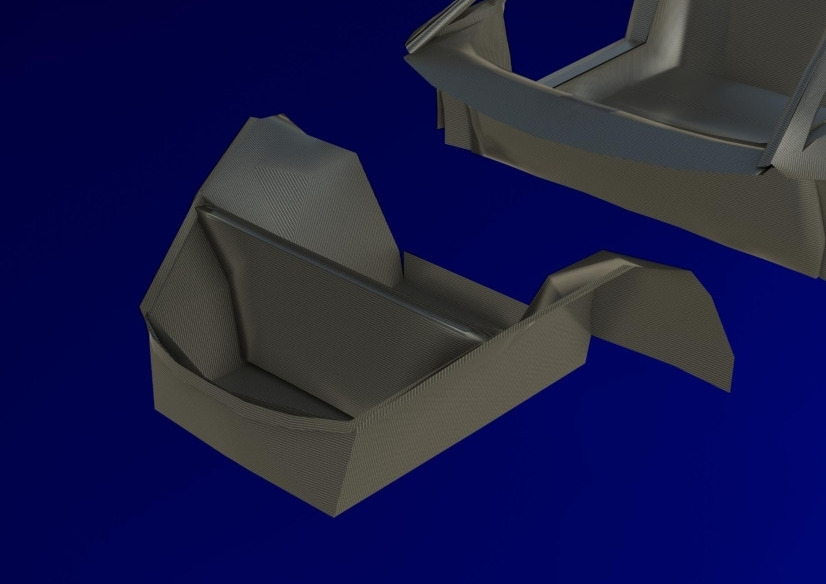

It has a fiberglass one-piece cockpit, left and right sidewalls with rear fenders, roof and front fenders. The resulting body structure is uneven. Its individual parts have different rigidity and, therefore, different resistance. shock in road accidents. As a result, in collisions of the car due to the deformation of the front and rear parts of the body, the impact energy is extinguished, and the passenger compartment is protected from deformation. This ensures that the survival space of people in vehicle collisions is maintained. The body of the DUBINA EVO is assembled on an assembly jig for the first stage of the production line. Two workers connect the bottom of the cockpit to the tunnel using epoxy glue, then the battery compartment is attached to the bottom of the cockpit, then the front and rear are attached part, then the left half and the right half at the end of the roof is installed.

Бесплатный фрагмент закончился.

Купите книгу, чтобы продолжить чтение.