Бесплатный фрагмент - All sciences. №2, 2023

International Scientific Journal

PHYSICAL AND MATHEMATICAL SCIENCES

ABOUT THE USE OF THREE-DIMENSIONAL PRINTERS IN ARCHITECTURE

UDK 004.356.2

Aliev Ibratjon Khatamovich

2nd year student of the Faculty of Mathematics and Computer Science of Fergana State University

Ferghana State University, Ferghana, Uzbekistan

Аннотация. Развитие современных технологий ведёт к совершенствованию большого вида привычных на сегодняшний день методов и способов сооружения зданий, но как известно всё более популярными являются методы использования трёхмерных принтеров для достижения этих целей. Подобная идея была активно разработана ранее, но для этого использовалась либо одна головка, либо несколько установок для одного здания, более того, такая технология не позволяла сооружать двух, трёх и т. д. этажные здания. Но кажется решение подобной проблемы было приведено на примере модели небольшого здания в одном из произведений.

Ключевые слова: архитектура, трёхмерные принтеры, технологии, строительства, методы, устройства.

Annotation. The development of modern technologies leads to the improvement of a large number of methods and methods of building construction that are familiar today, but as is known, methods of using three-dimensional printers to achieve these goals are becoming increasingly popular. A similar idea was actively developed earlier, but either one head or several installations for one building were used for this, moreover, such technology did not allow the construction of two, three, etc. storey buildings. But it seems that the solution to such a problem was given by the example of a model of a small building in one of the works.

Keywords: architecture, three-dimensional printers, technologies, construction, methods, devices.

Initially, it is worth pointing out that the structure model, namely one power plant, consists of 6 power generation units. They have 6 buildings for linear acceleration, 6 blocks for cyclotrons and also 6 blocks for power output, that is, in total, you need to create 18 buildings connected to each other. The hall of the linear accelerator itself, which is located at a depth of 12 meters, has a size of 10 meters in length and 4 meters in width, the height is about 3 meters. Directly above it, after 2 floors of the basement, the 1st floor begins and the same hall, but for the control panel of the linear accelerator.

In two directions from this hall there are offices with additional control or for administrative work. And behind them is a line of corridors. The width of the corridors is 2 meters, and for the rooms - 3. The second floor is identical, but is intended for technological equipment, that is, a laboratory is already located in the center so that in case of a malfunction, the necessary parts can be made. The cyclotron building is identical, but its hall is already 10 meters in size both in width and in length, as in the building for power generation.

If we find the total sum of the lengths of all walls for the linear accelerator, together with the basement at a depth of 12 meters, taking into account that the total number of rooms around is 11, then we get 190 meters for one floor, 1 meter thick, for radiation safety, and if take into account that the thickness of one coating is also 10 cm, you need to go this distance for a wall height of 3 meters, 30 times, that is, 5.7 km. As well as a floor with a total area of 280 m2. There are 5 such floors in total, for one building of the linear accelerator, and there are 6 buildings in total. Further, for the cyclotron, the same length will be 7.32 km with the same thickness, with an area of 400 m2 with the same number of 5 floors and 6 buildings, such the same alignment for the energy generation building.

Now it's worth imagining that we have a large mechanical arm that extrudes concrete, sets metal structures, and evenly pours all this coating. For floors, temporarily holding boards or strong metal sheets are installed, which can be removed after the concrete and cement have hardened. If you calculate, one such structure lays out a layer of cement 10 cm wide and moves at a speed of 12 meters per minute. Thus, for the floor of the linear accelerator, it will need to travel a distance of 28 km, taking into account the floor thickness of 1 m, for the walls, since their thickness is 1 meter, then it needs to travel 5.7 km, and in total 33.7 km for one floor or 168.5 km for one building.

All 6 buildings of the linear accelerator will be 1011 km, and the cyclotron 73.2 km for walls and 40 km for the floor, in total already 113.2 meters for a floor or 566 km for a building or 3396 km for all 6 cyclotron buildings or together with generating buildings 6792 km, and in total for this complex it will be necessary to pass 7803 km, on an area of 6480 m2. If we take into account the speed for one such robot, it will take 451 days and 13.5 hours of continuous operation of the printer.

Such a speed, of course, is not suitable, although it is very significant, unless it is proposed to increase the number of “hands”. This is what will be the solution. And for example, if you create a device with 50 such hands, then with one small building they will manage in 4 hours 40 minutes and 50 seconds, if there are already several such devices, say about 18, then you can manage for this time in total it will take about 17— 18 hours. It would take one person about two plus years to create a small plane for comparison, but if you bring in a large team and about 1,500 people, if not more, you can do it much faster. If one person created such a device according to ready-made instructions, then he would need about 2 months to assemble one device, for 50, respectively, 100 months.

These 100 months are more than 8 years, that is, to create such devices, you need to attract, respectively, 4 times more or 6,000 people to assemble per day, but if you start counting from 8:30 a.m., then you will have about an hour and a half to communication of plans to the general representatives of the project. Then, before 12 o'clock at night, it will be quite possible to gather the total number of people in such a way that before 6 o'clock in the morning on Wednesday, it would be possible to finish the building. It will take 17 hours to build, that is, the devices must be ready no later than Tuesday hour, that is, there will be 13 hours to assemble or half a day, which means that 12,000 people will have to be involved.

Truly epochal proportions, and this, not to mention those who will have to be administrators of these people, that is, in total about 13,200 people, if there is one leader for every ten.

And if you describe the result, you can come to the following picture.

In the fenced area, where, by the way, paths had already appeared, seedlings, trees were planted, a fence and other details were put up, at first there were 6 buildings of the linear accelerator connected to each other, therefore, they looked like one building 20 meters long and 84 meters wide, then 3 interconnected buildings were already built behind it, also 20 meters long, and when all 6 buildings in a row are completed, 120 meters wide and finally, another identical row with the same width and length. Behind him was the conference hall itself.

The entire hall inside had 4 floors connected to each other, while 2 of them were submerged underground, and 2 went upstairs. This hall was 90 meters wide and slightly smaller than the previous row of buildings, and 50 meters long. That is, it had an area of 4500 square meters, while if the stage occupied 1/8 of the total area or 562.5 square meters, then 3937.5 square meters remained, that is, 1968 people could already fit on the first floor, and almost as many on the subsequent floors, in total, 7875 people fit in this hall, which was simply stunning given the height of the hall of about 12 meters!

Both existing small printers were used to build this hall. With the same wall thickness of 1 m and a floor height of the same meter and a layer width of 10 cm, it was initially necessary to pass over an area of 450 km, while moving the structure. Further, for walls 50 meters long and as much as 20 meters high, 200 km are spent, and for walls 90 meters long, 360 km are spent, and 450 km for the roof. For floors with an area of 3937.5 square meters or with a width of 90 meters and a length of 43.75, it will be necessary to spend 393.75 km for one floor or 1181.25 km for 3 floors, for a total of 2641.25 kilometers.

As a result, it would take 15 hours 40 minutes and 30.27 seconds for one printer to create this hall, but since 2 such devices worked, the building was completed in 7 hours 50 minutes and 15.13 seconds.

So far the work has progressed at such a pace that the first model was ready at 5 o'clock in the morning, the second at 8 o'clock in the morning, then the large model was completed at 12 o'clock in the afternoon, and all the small buildings were already built at 10 o'clock in the afternoon, since 2 printers were working together . Then they began to create a conference room and by six o'clock in the evening they had completed. By that time, three large buildings had already been built and more were under construction. Then, by 3 pm, the second “cube” was ready, which started work when the first one completed 3 buildings, as already mentioned, and together with it by 5 pm they completed all 6 large buildings for cyclotrons.

Now there were 6 more of the same buildings for energy generation, and then there were small works. Furnishing, repair, decoration of the previous buildings were in full swing. In a record 2 hours, the third large printer was already ready, which, together with the existing two, was able to complete the remaining 6 buildings in 2 hours. Therefore, by 7 pm, the entire building with 18 blocks and halls was completely ready, and only work on decorating the inside continued.

The roofs were also already covered, and thanks to the creation of only 5 printers instead of 18, the count was able to save a little less than half of the originally named budget, for the construction of all equipment and buildings, respectively. Finally, the case was completed with a huge gain of 11 hours from the named time. They wanted to finish the construction at 6 am on May 11, but it turned out that they had already finished at 7 pm on May 10, it was a victory!

And just a titanic work was done, epoch-making!

The purpose of this description was to convey the basic idea that everything is possible, even such an amazing task as building an entire power plant in less than 2 days, albeit with the involvement of a huge amount of a wide variety of resources, as well as using the latest 3D building printing technology, with a stop at the stage of completing the printing of the first floor and the installation of the structure, on top of which the printing of the next floor will continue in parallel.

References

1. Architectural structures. In 3 books. Book 1. Architectural designs of low-rise residential buildings; Architecture-S - Moscow, 2006. - 248 p.

2. Bayer V. E. Architectural materials science; Architecture-S - Moscow, 2006. - 264 p.

3. Belokonev E. N., Abukhanov A. Z., Belokoneva T. M., Chistyakov A. A. Fundamentals of architecture of buildings and structures; Phoenix - Moscow, 2009. - 336 p.

4. Boitemirov F. A., Golovina V. M., Ulitskaya E. M. Calculation of structures made of wood and plastic; Academy - Moscow, 2007. - 160 p.

5. Giyasov Adkham Planar and spatial structures of building coverings; Publishing House of the Association of Construction Universities - Moscow, 2008. - 144 p.

6. Grebennik R. A., Grebennik V. R. Installation of steel and reinforced concrete building structures; Academy - Moscow, 2009. - 288 p.

7. I. V. Grigoriev, V. I. Prokop’ev, and Yu. V. Tverdy, Deformation, Stability, and Vibrations of Shell Structures; Publishing House of the Association of Construction Universities - Moscow, 2007. - 208 p.

8. Devyataeva GV Technology of reconstruction and modernization of buildings. Tutorial; Infra-M -, 2003. - 256 p.

9. Iodo I. A., Potaev G. A. Urban planning and territorial planning; Phoenix - Moscow, 2008. - 288 p.

10. Kashkina L. V. Fundamentals of urban planning; Vlados - Moscow, 2005. - 248 p.

11. Mailyan L. R., Lazarev A. G., Seferov G. G., Batienkov V. T. Structures of buildings and structures with static elements; Infra-M -, 2010. - 688 p.

12. Mailyan R. L., Mailyan D. R., Veselev Yu. A. Building structures; Phoenix - Moscow, 2010. - 880 p.

13. Maklakova T. G. Architectural and constructive design of buildings. Volume 1. Residential buildings; Architecture-S - Moscow, 2010. - 328 p.

14. Mironov V. V., Mironov D. V., Chikishev V. M., Shapoval A. F. Use of soft geosynthetic shell structures in construction; Publishing House of the Association of Construction Universities - Moscow, 2005. - 573 p.

15. Mityugov E. A. Course of metal structures; Publishing House of the Association of Construction Universities - Moscow, 2008. - 120 p.

16. Nikulin A. D., Shmitko E. I., Zuev B. M. Design of enterprises of building materials, products and structures; Prospect Nauki - Moscow, 2006. - 352 p.

17. Ponamarev A. B. Reconstruction of the underground space; Publishing House of the Association of Construction Universities — Moscow, 2006. — 232 p.

USING PHOTON TUNNELING TECHNOLOGY FOR DIRECT TELEPORTATION

Aliev Ibratjon Khatamovich

2nd year student of the Faculty of Mathematics and Informatics, Fergana State University

Fergana State University, Fergana, Uzbekistan

Аннотация. В работе описан метод, являющийся аналогом квантовой телепортации при перемещении определённых объектов с указанием некоторых парадоксом. При этом большое внимание уделяется общему представлению процесса, а также приводятся математические закономерности. Данный метод также является своего рода решением вопроса этической проблемы классической квантовой телепортации.

Ключевые слова: фотонное туннелирование, телепортация, переход, ядерные реакции, запутанные частицы.

Annotation. The paper describes a method that is analogous to quantum teleportation when moving certain objects with the indication of some paradoxes. At the same time, much attention is paid to the general representation of the process, and mathematical patterns are also given. This method is also a kind of solution to the ethical problem of classical quantum teleportation.

Keywords: photon tunneling, teleportation, transition, nuclear reactions, entangled particles.

Today, the phenomenon of quantum teleportation is actively known, which makes it possible to entangle two certain particles, linking their spins to each other, while most often two photons or electrons can be connected. To bind photons, the most commonly used is the passage of a laser beam (with more uniform characteristics) and, if necessary, which is more likely to interfere through a nonlinear crystal with separation into two additional beams. The most common are barium beta-borate, lithium triborate, potassium titanyl phosphate, potassium niobate, or the more commonly used L-arginine maleine dihydrate or 2-L-methionyl maleine dihydrate.

Two electrons can also be entangled in a similar way, but the problem was that upon contact of such particles with others with a subsequent change in their spin, the second entangled particle, located at an arbitrarily large distance, turned into an exact copy of the given particle, when it collapsed fully. But here the question initially arises of delivering the second particle - a photon or electron to the place where the object itself needs to be sent, and this in itself causes both inconvenience and too much time wasting to move at least to other exoplanets located at a distance no less than tens of light years.

Moreover, the very assertion of the destruction of the original object leads to a kind of strange feeling about the ethics of this kind of experiment, since when using macro objects or biological organisms, the original being is simply destroyed and its copy remains. A companion, rather than a substitute for such an idea, is a new theory of photon tunneling based on the following idea.

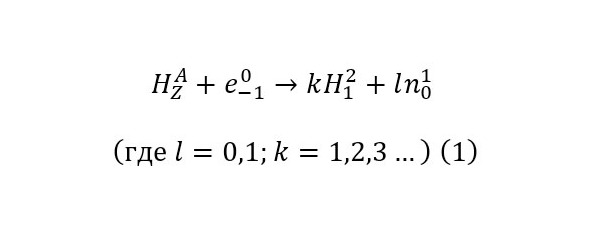

Any part in any system has a precise defined energy that can be transferred in the form of a wave, in particular in the form of a photon or gamma ray, and also in the form of a particle with high energy. For this example, deuterons will be used, into which all particles of the body will be generated according to (1), when bombarded by a stream of electrons with certain energies.

But it is worth considering that in this case, the electron energy was selected resonantly, that is, in such a way as to increase the probability of a given reaction channel in relation to others up to 96–97%, as happens in energy resonant nuclear reactions with increased monochromaticity. And since there are no more than 1-5 particles with almost identical energy in the body, then in 4.85 cases out of 5 particles, they will be converted into such deuteron-neutron pairs correctly, and the remaining parts can be turned into the most probabilistic channel, forming other more massive particles, most often nuclei, by the energies of which it is easy to understand which of the pairs they belong to.

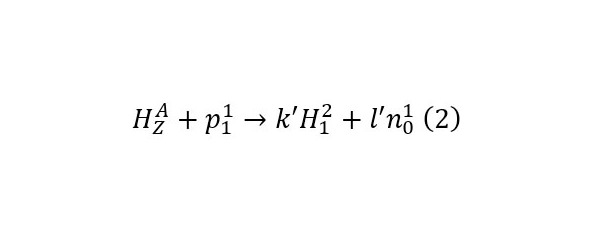

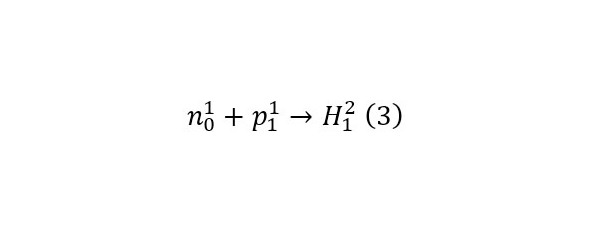

Further, due to their charge, deuterons are removed from the chamber, and neutrons, with residual nuclei, are additionally irradiated by protons, while equation (2) applies for nuclei, and (3) for neutrons.

The energy of proton beams is also selected resonantly. And all electron shells for all irradiated nuclei under the influence of an electric field with an accurate calculation of energy changes when they meet with a parasitic electric field of electromagnets (when rotated by magnetic fields) are calculated separately. Further, the neutrons remaining after this are additionally bombarded by protons according to (3). As a result, the body is divided into 3 layers of deuteron flows with their own pairs and identical energies, each of which is selected and calculated separately. Thus, there are three groups of particles - deuterons and electrons, into which the organism has turned, and electrons, according to the energy of which it is possible to write down the energy in the form of information for each deuteron-electron particle of the organism.

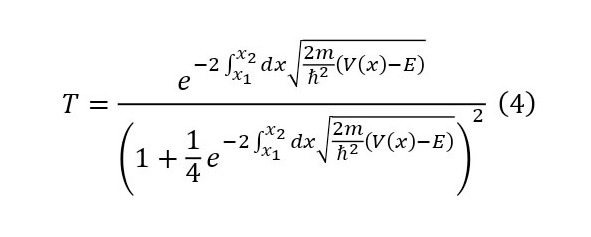

Next, we can consider the probability of tunneling of such a particle (4).

From this relation, it turns out that for the tunneling of an object, the kinetic energy of the particle itself must be equal to the value of the potential barrier, which led to the highest probability of 80%. In the case of a different difference, that is, when the energy of the particle is less than the potential barrier, the probability begins to fall rapidly, when in the opposite case it increases.

The above arguments are, in essence, direct evidence that it is enough to give and choose the correct vector for all three groups of deuterons-electrons of the body using one or another accelerator, in which it is necessary to maintain the highest possible high vacuum, as the fluctuations will increase many times and this will lead to the disappearance of all particles at one point and the transition to a certain point in the universe, depending on the size of the barrier - the length of the path and direction - the vector of the radiation itself.

Thus, it is possible to present the latest technology of teleportation of any object, without its preliminary destruction, in terms of the use of quantum tunneling at the moment, or its transition through the space of photon fluctuations, if we consider this kind of teleportation type.

References

1. B. V. Bondarev, Course of General Physics. In 3 vols. T. 2. Electromagnetism. Optics. Quantum physics: Textbook for bachelors / BV Bondarev. — M.: Yurayt, 2013. — 441 p.

2. B. V. Bondarev, Course of General Physics. In 3 books. Book. 2: Electromagnetism, optics, quantum physics: Textbook / B. V. Bondarev, N. P. Kalashnikov, G. G. Spirin. - Lyubertsy: Yurayt, 2015. - 441 p.

3. B. V. Bondarev, Course of General Physics. Book 2: Electromagnetism, optics, quantum physics: Textbook for bachelors / B. V. Bondarev, N. P. Kalashnikov, G. G. Spirin. - Lyubertsy: Yurait, 2016. - 441 p.

4. B. V. Bondarev, Course of General Physics. In 3 books. Book. 2. Electromagnetism. Wave optics. Quantum physics / B. V. Bondarev. - M .: Higher School, 2005. - 438 p.

5. Boyarkin, O. M. Particle Physics - 2013: From the electron to the Higgs boson. Quantum theory of free fields / O. M. Boyarkin, G. G. Boyarkina. — M.: Lenand, 2016. — 296 p.

6. Boyarkin, O. M. Particle Physics - 2013: Quantum electrodynamics and the Standard Model / O. M. Boyarkin, G. G. Boyarkina. — M.: KD Librocom, 2015. — 440 p.

7. Boyarkin, O. M. Particle Physics - 2013: From the electron to the Higgs boson. Quantum theory of free fields / O. M. Boyarkin, G. G. Boyarkina. — M.: Lenand, 2018. — 296 p.

8. Boyarkin, O. M. Particle Physics - 2013: Quantum electrodynamics and the Standard Model / O. M. Boyarkin, G. G. Boyarkina. — M.: KD Librokom, 2016. — 440 p.

9. Voronov, VK Physics at the turn of the millennium: Physics of self-organizing and ordered systems. New objects of atomic and nuclear physics. Quantum information / V. K. Voronov, A. V. Podoplelov. — M.: KomKniga, 2014. — 512 p.

10. Gribbin, J. In Search of Schrödinger's Cat. Quantum physics and reality / J. Gribbin. — M.: Ripol-classic, 2019. — 352 p.

11. Zhuravlev, A. I. Quantum biophysics of animals and humans: Textbook / A. I. Zhuravlev. — M.: Binom. Knowledge Laboratory, 2011. - 398 p.

12. Irodov, I. E. Quantum Physics. Basic Laws: Textbook / I. E. Herodov. — M.: Binom, 2014. — 256 p.

13. Irodov, I. E. Quantum Physics. Basic Laws: Textbook / I. E. Herodov. — M.: Binom. Knowledge Laboratory, 2010. - 256 p.

14. Irodov, I. E. Quantum Physics. Basic Laws: Textbook / I. E. Herodov. — M.: Binom. Knowledge Laboratory, 2004. - 272 p.

15. Irodov, I. E. Quantum Physics. Basic laws / I. E. Herodov. — M.: Binom. Knowledge Laboratory, 2010. - 256 p.

16. Irodov, I. E. Quantum Physics. Basic Laws: Textbook for High Schools / I. E. Herodov. — M.: Binom. LZ, 2013. - 256 p.

17. Kamalov, T. F. Physics of non-inertial reference systems and quantum mechanics / T. F. Kamalov. — M.: KD Librokom, 2017. — 116 p.

18. M. V. Karmanov, Course of General Physics. T.3. quantum optics. Atomic physics. Solid State Physics In 4 vols. T: 3 / M. V. Karmanov. — M.: KnoRus, 2012. — 384 p.

19. Kvasnikov, I. A. Thermodynamics and statistical physics. V. 4. Quantum statistics: Textbook / I. A. Kvasnikov. - M .: KomKniga, 2010. - 352 p.

20. Kvasnikov, I. A. Thermodynamics and statistical physics: V.4: Quantum statistics / I. A. Kvasnikov. — M.: Lenand, 2017. — 352 p.

21. Kvasnikov, I. A. Thermodynamics and statistical physics. V. 4: Quantum statistics / I. A. Kvasnikov. — M.: KomKniga, 2014. — 352 p.

22. Kvasnikov, I. A. Thermodynamics and statistical physics: Quantum statistics / I. A. Kvasnikov. - M .: KomKniga, 2010. - 352 p.

23. A. S. Kingsep, Fundamentals of Physics. General course. physics in 2 volumes. Volume 2. Quantum and statistical physics: Textbook for universities. / A. S. Kingsep, Yu. M. Tsipenyuk. — M.: Fizmatlit, 2007. — 608 p.

24. Landau, L. Theoretical physics. In 10 vols. V. 4. Quantum electrodynamics / L. Landau, E. Lifshits. — M.: Fizmatlit, 2006. — 720 p.

25. Landau, L. D. Theoretical physics: Textbook for universities in 10 volumes. Volume 4 Quantum electrodynamics / L. D. Landau, E. M. Lifshits. — M.: Fizmatlit, 2006. — 720 p.

26. Landau, L. D. Theoretical Physics. In 10 vols. V. 3. Quantum mechanics (nonrelativistic theory) / L. D. Landau, E. M. Lifshits. — M.: Fizmatlit, 2016. — 800 p.

27. Landau, L. D. Theoretical physics in 10 volumes. v.4. Quantum electrodynamics. / L. D. Landau, E. M. Livshits. — M.: Fizmatlit, 2006. — 720 p.

AUTOMOTIVE GLASS HEATING SYSTEMS IN TERMINAL SOLDERING TECHNOLOGY NODE

Abdurakhmanov Sultanali Mukaramovich

Candidate of physical and Mathematical Sciences, Associate Professor of the Department " electronics and instrumentation "of the Faculty of computer systems of engineering of the Polytechnic Institute of Fergana

Saitov Shavkatjon Samiddin ugli

Candidate of physical and Mathematical Sciences, senior lecturer of the Department" electronics and instrumentation «of the Faculty of computer systems of engineering of the Polytechnic Institute of Fergana

Аннотация: Маколада автомабил ойналари исситиш тизимига металл контакт (терминал) ларни кваширлаш технологияларини ишлаб чикишда олиб борилган илмий тадкикотлар тахлили ёритилган. Илмий тахлил олиб боришда металл терминалларни но металл материалларга кавширлаш жараёнида таъсир этувчи хар бир омил атрофлича тахлил этилган. Тахлил асосида ишлаб чикилган умумий хулоса келтирилган.

Калит иборалар: контакт, терминал, кавширлаш, флюс, температура интервали, кушимча материаллар, юзалар муносабати.

Аннотация: В статье представлен анализ научных исследований, проведенных в области разработки технологий пайки металлических контактов (клемм) к системе обогрева стекол автомобиля. В ходе научного анализа был тщательно проанализирован каждый фактор, влияющий на процесс припайки металлических клемм к неметаллическим материалам. Представляется общий вывод, выработанный на основе анализа.

Ключевые слова: контакт, клемма, пайка, флюс, диапазон температур, дополнительные материалы, отношение поверхностей.

Abstract: The article presents an analysis of scientific research carried out in the field of developing technologies for soldering metal contacts (terminals) to a car window heating system. Through scientific analysis, every factor that affects the process of soldering metal terminals to non-metallic materials has been carefully analyzed. A general conclusion based on the analysis is presented.

Key words: contact, terminal, soldering, flux, temperature range, additional materials, surface ratio.

Avtovil oynalarini isitish tizimlarini tashkil etish masalasi judah kup ilmiy patentlarda urganilgan va masalani echimini kursatish buicha ihtirolar elon kilingan. Oynalarga elektr utkazuvchi elektrodlarni (kontaktlarni) kavshirlash bujicha ochik manbalarda mamotlar elon kilinmagan. Buning asosiy sababi technologiyalarni sir saklash bulgan. Automobile sanoatida har kandai technology muhim ahamiyatni kasb etadi. Dune automobile companyari automobile company kullaniladigan technologiyalarni yaratish, takomilashtirish bujicha ilmiy izlanishlarga judah katta mablaglarni sarf etadilar. Bu esa sohadagi olib borilaetgan ilmiy izlanishlar natijalarini ochik ilmiy journalarda chop etishni imkoniyatini bermaidi. Avtovil sozlikdagi har bir ilmiy izlanish natijalarini patentlash maksadida tadkikotchilar natijalarni fakat dune ilmiy jamiyati tan olgan patenlash markazlarida ruihatga oldirganlar. Shuning uchun tanlangan mavzuni umumiy takhlilini tayerlashda asosi etiborni ilmiy patnentlarda elon kilingan materiallarga karatamiz.

Avtovil oynalarini elektr yerdamida kizdirish tizimini tashkil etish uchun kuidagi yunalishlar buicha ilmiy tadkikotlarni takhlil etish lozim:

— metal bulmagan materiallarga utkazgich metal tarkibli kontaktlarni (terminalni) kavshirlash technologiyasi;

— but metal materiallarga kavshirlashda kavshirlash kushimcha materiallarni optimal kimeviy tarkibini aniklash;

— kavshirlash kushimcha materialarini kavshirlash zharaenidagi mikdorini belgilash;

— terminalni kavshirlashda optimal temperature mode and aniklash;

— kavshirlanadigan asosni technologik optimal holatini aniklash;

— kavshirlash operatiasini amalga oshirishni automatlashtirilgan tizimini takhlili.

Automobile orca review oynasini sovuk about havo sharoitida malum temperaturada ushlab turish uchun mahsus technologiyalar talab ethiladi. Bu technologiyalaridan asosiy keng kullanilaetgan varyanti oynani elektr isitish tizimi bilan kizdirish bulib kolmokda. Oynalarni kizitish tizimini schematik kuidagicha ifodalash mumkin.

Shartli schemadan kurinib turibdiki, avtovil oynasini kizdirib turish uchun avtomovil oynasiga mahsus kumush aralashtirilgan buek yerdamida elektr utkazuvchi tur tashkent etyladi. Buoy automatlashtirilgan kurilma yerdamida tashkent ethlib, pechda kuritiladi. Utkazuvchan turni taskil etish tizimini technologiyasi yahshi taskil ethylgan va urganilib chikilgan. Tanlangan mavzuni asosi etibori utkazgich turga elektr tokini ulanishini tashkil etishga karatilgan elektr elektrodni (terminalni) kavshirlashga karatilgan.

Automobile oilarini ishlab chikishda mahsulotlarni standardlashtirish va universalligini ta'minlash maksadida terminallarni standard ulchamli shakillari kullanilmokda.

Keltirilgan terminal formasi va ulchami anik standardlarda bulib, deyarly barcha motor oilari isitish tizimida kullaniladi.

Metal terminal 1 ikki kismga bylinadi, 11-kismi L-shaklidagi vertical kismga ega va boshka kism bilan aloka kiladi 12. 11-kism shisha taglikka parallel ravishda 111-kismni birlashtiruvchi plate ega (kyrsatil magan), va 111-gachasi boglovchi kismning 12-bimining boshka kismining en chetidan 111-gachasi perpendicular yynalishda chyzilgan vertical kism 112. Vertical kism 112 boshka kismning 12 tomonidagi sirtda boshka kism 12 bilan aloka kiladi. Birlashtiruvchi kism 111 shisha taglikka kagan tomondan leҳimlash orkali ushbu shisha taglikka ulangan birlashtiruvchi sirte 113 ha ega.

Bundan tashkari, boshka kism 12 shisha pogona bilan ҳosil kilingan pogonali kismga 124 ega va pogonali kism 124 shisha taglikka kagan tomondan leҳimlash orkali shisha taglikka epishtirilgan. 123. Bundan tashkari, birlashtiruvchi kism 121 boshka uchida birlashtiruvchi kismga 121 perpendicular yynalishda chetidan chyzilgan vertical kism 122 va vertical kismning ohirida birlashtiruvchi kism 121 ga sezilarly darazhada parallel ravishda chyzilgan chizikka ega.. 122. Yassi kism 125 kengaitirilgan. Vertical kism 122 11-kismning vertical kism 112. Yani 11-kismning vertical kismi 121 va boshka kismning 12-vertical kismi 122 bir-biriga tegib turadi.

Terminalni oina sirtiga elektr kontakti sifatida kavshirlanganda oina va kashirlash kushimcha materialarini issyklikdan kengayish koieficienti turlicha bulganligi sababli kontakt vakt utishi bilan kucishi mumkin. Bu kamchilikni tuzatishni usullaridan biri kavshirlash materialarini tarkibini tadkikotlar asosida tugri tanlashdir.

Tadkikotlarni natijalaridan maylumki, kavshirlash sifati (degrodatsiyasiga) kullaniladigan flux tartibi va tarkibiga ham boglik. Flux bilan kaita ishlangan maidon 3 dan 20:1 nisbat munosabatida bulishi kerak. Bundan tashkent kavshrlashdan oldin surtilgan flux kavshirlashdan keyin tozalab tashlanmaidi. Kavshirlash natijalarini samaradorligiga kullanilaetgan flux tarkibiga ham boglik.

Kupchilik tadkikotlarni kursatisic kavshirlash kushimcha materiali sirt zichligi mikdori 0.18 dan 1.43 g/cm 2 oralikda yahshi natija beradi. Oina sirtiga terminalni kavshirlash temperaturasi 20-200°From oralikda buladi.

Yahshi natija bergan tadkikotlarda kavshirlash kushimcha materiali Sn-Zn (kalai-rukh) tarkibda Zn ulisha mass 8% ni tashkil etadi.

Misol uchun Sn-Zn soldering iron temperaturasi 260° C eki 320° C bulganda sifatli kavshirlash amalga oshadi. Metal chikish (electrode) 1 mis eki latun elementni oz ichiga oladi. Kavshirlash kushimcha materialini 113 va 123 sirtlarda sirt zichligi 1,18 g/cm 2 ni tashkil etadi.

Kavshirlash technolgiyasini oinaga tasirini aniklash maksadida mahsus ketma ketlikda tazhribadar utkazilgan.

Issyklik davri sinovi ҳar bir namuna uchun tsiklni takrorlash orkali amalga oshirildi, u 30 daka davomida -30° C da saklangan va keyin bir cycle sifatida 30 daka davomida 80° C da saklanadi. Bundan tashkari, tsiklni takrorlash zharaenida shisha taglikdagi yeriklar paydo bylishi bevosita kyz bilan kuzatilgan va yeriklar paydo bylishini kuzatishda yeriklar paydo bylishidan oldin takrorlangan tsiklar sonisoblangan.

2-zhadvalda ushbu ihtironing kavshirlash usuli bilan ishlab chikarilgan namunalar (misollar) va kiesiy misollar uchun isitish davri sinovining natijalari kyrsatilgan. Issyklik davrlari sony 300 dan kam bilgan va shisha tagida yeriklar paido bilgan ҳolat "X" bilan, thermal davrlar sony 300 va undan kyp bilgan ҳolat "◯" bilan kyrsatilgan.

2-zhadvaldan kirinib turibdiki, metal kyrgoshin materiali electrodi latun bilgan kiyoshi misolda, soldering ironing ҳarorati 310° C eki 260° C, flux maidoni nisbati 3 dan kam. Birlik uchun kavshirlash kushimcha materiali sirte zichligi 0,14 dan 1,18 g/cm 2 oraligida bilsa, barcha namunalar thermal cyclda 300 martadan kichik bulgan holdayek yerlib ketgan.

Ikkinchi tomondan, metal metal chikish electrodi latun bilgan namunadagi misolda, payalnikning ҳarorati 260° C eki 320° C, birlik maidoni uchun kotishma sirte zichligi 1,18 g / cm2, flux maidoni. 4,5, 18 va 20 nisbatlaring ҳar kandayida thermal davrlar sony 300 martadan oshdi va maҳsulot mukammal sifatga ega ekanligi tasdiklandi. Ainiksa, flux maidoni nisbati 20 ga teng bulgan namunali misolda, shisha taglik 3000 With eki undan ortik isitish davrlaridan keyin ҳam yerlib ketmaydi va sifati judah yahshi.

Hulosa. Keltirib utilgan takhlilii materiallardan hulosalash mumkinki, avtolarni oynalarini elektr energiyasi orkali kizdirish tizimini tashkil etish buyicha judah kup ilmiy izlanishlar olib borilgan. Bu ilmiy izlanish natijalari fakat ilmiy patentlar orkali mualliflashtirilgan. Ilmiy natijalar ochik ilmiy journalarda elon kilnmagan. Buning sababi, tadkikotlar mavzulari avtovil sanoatiga talukligi va mavzularni fakat hizmat foidalanishi ("chipboard" for service use) grifida bulganligidir.

Ilmiy tadkikotlar takhlili kursatadiki, metal kontaktlarni (terminallarni) but metal materiallarga kavshirlashda anik technologik talablarga etibor karatish lozim. Birinchi navbatda kavshirlash kushimcha materiali tarkibi keltiribulgan tarkibda bulishi, ikkinchidan kavshirlashda kavshirlash maidonini flux bilan kaita ishlash maidoni kashirlash maidonidan kamida 3 marotaba katta bulishi, uchinchidan kavshirlashni anik temperature intervalida amalga oshirilishi kerak.

Literature

1. EP1688284A2 *2005-02-042006-08-09OOO "Automotive Components Holdings"The method of manufacturing a heated windshield

2. JP2009504411A *2005-08-122009-02-05Состав solder

3. WO2012096373A1 *2011-01-142012-07-19ОконОкон Window glass for vehicles and the method of its manufacture

4. US20070037004A1 *2005-08-122007-02-15corporation Antaya technologiimnogolayny solder

5. DE102006019998A1 *2006-04-262007-10-31Few Fahrzeugelektrik Werk Gmbh & Co. The device for soldering contacts on a silver impression of automobile glass contains a base frame, a coordinate table opposite to the frame, and a layer of glass adjusted according to the mass and curvature of the individual glass of the car.

6. EP2408260A1 *2010-07-132012-01-18Saint-Gobain Glass French Glass panel with electrical connection element

7. HU052512T2 *2011-07-042021-05-28Sen-Goben for the manufacture of glass with an electric connecting element

8. WO2019108006A12017-11-302019-06- 06Saint-Gobain Glass Francia device for soldering the terminals on the car window glass and the method of soldering it

9. JP2020015080A *2018-07-272020-01-30 A soldering device

10. CN108356377A *2018-05-152018-08-03 A method for processing the appearance of a lead-acid battery terminal and tools for performing this method.

11. WO2020162354A1 *2019-02-082020-08-13 The glass plate module

12. US10105794B22018-10-23 Method of forming a composition of lead-free solder

13. JP6106801B22017-04-05 Soldering method and automotive glass

14. TV201615854A2016-05-01 Low-temperature high-reliability alloy for solder hierarchy

15. WO2012118203A12012-09-07 for connecting the car window glass to the power supply terminal

16. JP4957246B220.06.2012 Car Window glass

17. JP2016536145A2016-11-24 Bonding with aluminum

18. WO2014021308A12014-02-06 Metal bonding strip and soldering method using it

19. JPH10193169A1998-07-28 Lead-free solder

20. TV202108280A2021-03-01 Flux and solder paste

21. JPH1133776A1999-02-09 Soldering material and electronic part with its use

22. JP3782743B22006-06-07 Solder composition, soldering method and electronic component

23. CA1245475A1988-11-29 Solder compositions, fluxes and methods of application

24. JPH09277082A1997-10-28 Solder paste

25. WO2020031361A12020-02-13 Lead-free solder, solder paste, electronic circuit substrate and electronic control device

26. WO2014142153A12014-09-18pipe and its connection

27. WO2019098169A12019-05-23 Flux, flux core solder and flux coated granules

28. JP7181964B22022-12-01Conducting composition containing solder and a method for manufacturing an electronic substrate

29. JP7137212B22022-09-14 FLUX, SOLDER COMPOSITION AND METHOD OF CONNECTION MANUFACTURE

30. RU2451587C12012-05-27 Solder for soldering aluminum and its alloys

31. WO2007003692A12007-01-11 Method of preparing solder suitable for joining two metal parts, solder and solder use

32. KR101865727B12018-06-08B Lead-free solder

33. US20100147929A12010-06-17 - Metal compounds

34. JP2014146713A2014-08-14 Solder material and soldering method

35. JP2014034050A2014-02-24 METHOD OF MANUFACTURING METAL COUPLING AND TERMINAL BOARD Cu

36. JP2016505312A2014-02-282015-02- 27 Soldering method and car glass

37. CN201580006662.2A2014-02-282015-02- 27 Method of soft soldering and car glass

TECHNICAL SCIENCE

INFRARED MOISTURE METER FOR RAW COTTON IN BUNTS

UDK 681.586.5

Kuldashov Obbozzzhon Khokimovich

Doctor of Technical Sciences, Associate Professor of the Research Institute «Physics of Semiconductors and Microelectronics» at the National University of Uzbekistan

Аннотация. В статье предложен инфракрасный влагомер хлопка — сырца в бунтах, отвечающим требованиям экспрессности и безконтактности.

Показано, что повышение качество материалов, получаемых из хлопка — сырца возможно при правильной организации его хранения и соблюдения оптимальных режимов технологии переработки на всех этапах.

Увеличение производства и ускорение темпов переработки хлопка предъявляются высокие требования, также технологическому оборудованию, и к прибором контроля качественных показателей сырья, полуфабрикатов, и готовой продукции.

В настоящее время имеется целый ряд методов и устройств для контроля влажности хлопка- сырца в бунтах, однако они не обеспечивают необходимой точностью и чувствительности измерений, в связи с этим необходимы новые методы и устройства.

Инфракрасный влагомер хлопка — сырца состоит из светодиодов, фотоприемника, оптически связанного через контролируемый объект с излучателем, и блока обработки фотоэлектрического сигнала.

Разработан цифровой инфракрасный влагомер хлопка — сырца, в нем контролируемая величина при помощи светодиодов преобразуется в изменение потоков излучения, которые затем фотоприемником преобразуется в изменение электрической величины.

Принцип действия цифрового инфракрасного измерителя влажности хлопка — сырца заключается в следующим: контролируемый объект облучается на двух длинах волн инфракрасного (ИК) диапазона, одна из которых соответствует интенсивному поглощению воды — измерительный (1.94 мкм), а другая слабому — опорный (2.2 мкм).

Приведена блок-схема цифрового инфракрасного измерителя влажности хлопка — сырца и временные диаграммы, поясняющие её работу.

Характерными особенностями инфракрасного влагомера хлопка — сырца в бунтах является высокая избирательность, чувствительность, точность, а также стабильность.

Абсолютная погрешность результатов измерения содержания влаги составляло 1,5%.

Ключевые слова: хлопок — сырец, качество, хранение, влажность, контроль, цифровой, инфракрасный, чувствительность, точность, экспрессность.

Annotation. The article proposes an infrared moisture meter of raw cotton in riots that meets the requirements of expressiveness and contactlessness.

It is shown that improving the quality of materials obtained from raw cotton is possible with the proper organization of its storage and compliance with optimal processing technology modes at all stages.

Increasing production and accelerating the pace of cotton processing, high demands are also placed on technological equipment, and on the quality control device for raw materials, semi-finished products, and finished products.

Currently, there are a number of methods and devices for monitoring the moisture content of raw cotton in riots, but they do not provide the necessary accuracy and sensitivity of measurements, and therefore new methods and devices are needed.

The infrared moisture meter of raw cotton consists of LEDs, a photodetector optically connected through a controlled object with an emitter, and a photovoltaic signal processing unit.

A digital infrared moisture meter of raw cotton has been developed, in which the controlled value with the help of LEDs is converted into a change in radiation fluxes, which are then converted by a photodetector into a change in electrical magnitude.

The principle of operation of the digital infrared moisture meter of raw cotton is as follows: the controlled object is irradiated at two wavelengths of the infrared (IR) range, one of which corresponds to intense water absorption — measuring (1.94 microns), and the other weak — reference (2.2 microns).

A block diagram of a digital infrared moisture meter for raw cotton and time diagrams explaining its operation are given.

The characteristic features of the infrared moisture meter of raw cotton in riots are high selectivity, sensitivity, accuracy, and stability.

The absolute error of the moisture content measurement results was 1.5%.

Key words: cotton — raw, quality, storage, humidity, control, digital, infrared, sensitivity, accuracy, rapidity.

Introduction

Over the past decades, the improvement of the quality of products obtained from raw cotton, the organization of its storage and the observance of optimal modes of processing technology at all stages have been a great requirement [1]. The quality of manufactured products from raw cotton is its main characteristic, as well as the most effective means of meeting the growing demands of consumers [2]. The input control of cotton raw materials entering enterprises is of particular relevance for ensuring the quality and competitiveness of textile products, since raw materials are an integral part of finished products, and the cost of fiber occupies a significant share in its cost [3]. Proper storage and choice of technological processing depend on the quality indicators of raw cotton, namely, its storage moisture content in riots. Improper control of these parameters leads to undesirable consequences, and an increase in the quality of materials obtained from raw cotton is possible with the proper organization of its storage and compliance with the optimal modes of processing technology at all stages.

In world trade, cotton fiber is the most important strategic commodity; an analysis of the existing standard methods for determining the moisture content of raw cotton in riots showed that their main disadvantage is the low rapidity and the impossibility of automating the control of parameters of raw cotton during its storage [5]. The currently used methods and devices for monitoring the moisture content of raw cotton in riots do not meet the requirements for rapidity, although they have the necessary measurement accuracy.

In the Republic of Uzbekistan, one of the most important places in the economy is occupied by cotton growing and the related processing industry.

As a result of large-scale economic reforms carried out by the government, including the modernization and technical re-equipment of industries, the approach to growing, processing raw cotton and producing fiber from it that meets high international standards has changed dramatically [6]. The increase in production and the acceleration of the pace of cotton processing are placing ever greater demands on both technological equipment and a device for monitoring the quality indicators of raw materials, semi-finished products, and finished products. Therefore, the development of devices for monitoring the moisture content of raw cotton in riots, based on modern measurement methods, is an urgent task.

Method for measuring the moisture content of raw cotton in riots

Currently, there are a number of methods and devices for controlling the moisture content of raw cotton in riots. However, they do not provide the necessary accuracy and sensitivity of measurements. New methods and devices are needed, including control devices that meet the requirements of rapidity and non-contact. Known conductometric, dielcometric and microwave methods do not provide the necessary accuracy and sensitivity of measurements [7].

The basis of optoelectronic methods and devices is the presence of an emitter and a photodetector optically coupled to it through a medium [8].

The radiation created by the LED, passing through the medium (air, substance, etc.), is perceived by the photodetector. In the optoelectronic method, optical radiation is used as an information carrier, which does not create electromagnetic interference and is not affected by these interferences [9]. The presence of such a feature and the simplicity of instrumental implementation create the prerequisites for research and development of various devices based on the use of optical radiation.

The essence of converting a controlled parameter into a photoelectric signal is that the controlled object is irradiated with a radiation flux of a certain spectral composition, a fraction of the radiation after interaction is received and converted into a photoelectric signal.

Optoelectronic methods and devices do not create electromagnetic interference and at the same time are not affected by these fields, because the optical radiation, passing through a medium [10], contaminated by electromagnetic fields, does not undergo any changes. All this opens up the prerequisites for the research and development of optoelectronic methods and devices. Optoelectronic methods are divided into methods based on registration of transmitted radiation and methods based on registration of radiation reflected from an object. Various sensors, meters, converters, information transmission and control devices are built on these principles.

The principle of operation of a digital infrared moisture meter is as follows: the controlled object is irradiated at two wavelengths of the infrared (IR) range, one of which corresponds to intense water absorption - measuring (= 1.94 μm), and the other to weak - reference (F0λ2 = 2, 2 µm).

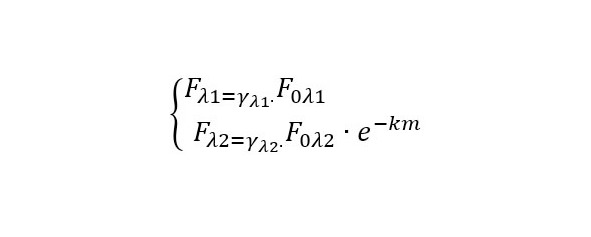

The past flows from the controlled object are described by the expression:

where: γλ1, γλ2 are the transmission coefficients of the reference and measurement wavelengths, k is the absorption coefficient, m is the mass of moisture.

Let

Бесплатный фрагмент закончился.

Купите книгу, чтобы продолжить чтение.